Master Setting Discs

Master setting discs are used to calibrate and set comparators, adjustable snap gages, automated electronic, pneumatic, microprocessor based gages and other precision measuring instruments that are used to check parts. Master discs are specified sometimes as setting discs. Designed to satisfy quality control traceability requirements.

Available in 3 styles. Style 1 and 3 - Tolerances are applied bilaterally; Style 2 - tolerances are applied unilaterally to the sections; minus on the "GO" section and plus on the "NOGO. Above 1.510 they are manufactured with a through hole. Larger sizes are manufactured with lightning holes. The removal of excess material from the web diameter lightens up the weight for easier use by the operator. WESTport Gage will always manufacture master discs larger than 8.010 using the trilock style and not the annular style described in B47.1

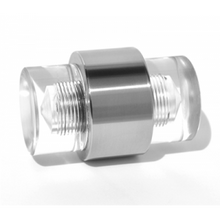

Below 1.510 are manufactured with nibs on both ends that are used in manufacturing and later used to glue on an insulating grip as pictured below. The roundness and taper of master setting discs does not exceed 50% of the gagemakers size tolerance and is non cumulative.

Supplied with insulator grips to prevent heat distortion. Style #3 master setting are separated by an A.G.D. separator plate and linked together with a tie rod and insulators. Manufactured per ANSI/ASME B47.1. Each setting disc is ring lapped to size and hand polished providing for superior accuracy and ensuring maximum gage wearability.

Master setting discs are available in Class XX, X and Z in steel, chrome or carbide. Sizes up to 23" in style #3. Setting discs above 8.010 are trilock design. Sizes above 1.510" to and including 8.510" (AGD standards call for style #3 in place of style #2). Style #3 master setting discs are separated by an (AGD) separator plate and linked together with a tie rod and insulators. XXX and Carbide set discs are priced on request. Traceable to NIST (National Institute of Standards and Technology)

Available in 3 styles. Style 1 and 3 - Tolerances are applied bilaterally; Style 2 - tolerances are applied unilaterally to the sections; minus on the "GO" section and plus on the "NOGO. Above 1.510 they are manufactured with a through hole. Larger sizes are manufactured with lightning holes. The removal of excess material from the web diameter lightens up the weight for easier use by the operator. WESTport Gage will always manufacture master discs larger than 8.010 using the trilock style and not the annular style described in B47.1

Below 1.510 are manufactured with nibs on both ends that are used in manufacturing and later used to glue on an insulating grip as pictured below. The roundness and taper of master setting discs does not exceed 50% of the gagemakers size tolerance and is non cumulative.

Supplied with insulator grips to prevent heat distortion. Style #3 master setting are separated by an A.G.D. separator plate and linked together with a tie rod and insulators. Manufactured per ANSI/ASME B47.1. Each setting disc is ring lapped to size and hand polished providing for superior accuracy and ensuring maximum gage wearability.

Master setting discs are available in Class XX, X and Z in steel, chrome or carbide. Sizes up to 23" in style #3. Setting discs above 8.010 are trilock design. Sizes above 1.510" to and including 8.510" (AGD standards call for style #3 in place of style #2). Style #3 master setting discs are separated by an (AGD) separator plate and linked together with a tie rod and insulators. XXX and Carbide set discs are priced on request. Traceable to NIST (National Institute of Standards and Technology)