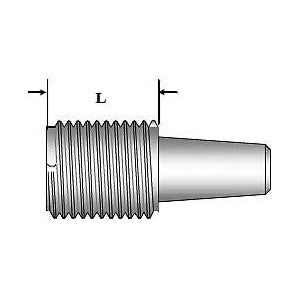

Master Setting Plugs

Master Setting Plugs Class "W" - Full form for TRI-ROLL and STC Comparators

- Precision Calibration: Class W master setting plugs ensure precise calibration of the Tri-Roll Comparator, leading to accurate measurements of external threads.

- Reference Standard: These setting plugs serve as a reference standard for the pitch diameter, offering a known and reliable dimension for setting and verification.

- Tight Tolerance: Class W designation signifies a very tight tolerance, ensuring that the master setting plugs meet stringent accuracy requirements.

- Consistent Measurements: The use of master setting plugs ensures that the Tri-Roll Comparator provides consistent and reliable measurements over time.

- Quality Control: Regular calibration and verification with Class W master setting plugs contribute to effective quality control processes in threaded component manufacturing.

- Adaptability: Master setting plugs can be easily interchanged, accommodating various thread sizes and designs, enhancing the versatility of the Tri-Roll Comparator.

- Durability: Crafted from materials like tool steel or tungsten carbide, these setting plugs are durable, offering long-term reliability and stability in calibration.

- Time Efficiency: Calibration with master setting plugs is a swift process, contributing to time efficiency in the inspection workflow.

- Cost-Effectiveness: Ensures that the Tri-Roll Comparator is set accurately, reducing the likelihood of producing defective parts and contributing to overall cost-effectiveness.

| PRODUCT NAME | GAGE SIZE | LENGTH | PRICE | SALE PRICE |

| 15903 | 2-56 (.086) | 1/4 | $141.00 | |

| 15916 | 10-32 (.190) | 13/32 | $125.00 | |

| 15959 | M12 x 1.25 | 3/4 | $140.00 | |

| 15958 | M12 x 1.75 | 3/4 | $140.00 | |

| 15955 | M8 x 1.25 | 1/2 | $125.00 | |

| 15952 | M4 x .7 | 13/32 | $148.00 | |

| 15951 | M3 x .5 | 5/16 | $150.00 | |

| 15950 | M2.5 x .45 | 1/4 | $150.00 | |

| 15949 | M2 x 4 | 1/4 | $150.00 | |

| 15947 | 1 1/2-12 | 1 | $287.00 | |

| 15946 | 1 1/2-6 | 1-1/4 | $310.00 | |

| 15945 | 1 3/8-12 | 1 | $297.00 | |

| 15944 | 1 3/8-6 | 1-1/4 | $297.00 | |

| 15943 | 1 1/4-12 | 1 | $261.00 | |

| 15942 | 1 1/4-7 | 1-1/4 | $261.00 | |

| 15941 | 1 1/8-12 | 1 | $239.00 | |

| 15940 | 1 1/8-7 | 1 | $239.00 | |

| 15939 | 1-14 | 1 | $203.00 | |

| 15938 | 1-12 | 1 | $203.00 | |

| 15937 | 1-8 | 1 | $203.00 | |

| 15936 | 7/8-14 | 1 | $185.00 | |

| 15935 | 7/8-9 | 1 | $185.00 | |

| 15934 | 3/4-16 | 7/8 | $150.00 | |

| 15933 | 3/4-10 | 7/8 | $150.00 | |

| 15932 | 5/8-18 | 7/8 | $130.00 | |

| 15931 | 5/8-11 | 7/8 | $130.00 | |

| 15930 | 9/16-18 | 7/8 | $130.00 | |

| 15929 | 9/16-12 | 7/8 | $130.00 | |

| 15928 | 1/2-20 | 3/4 | $115.00 | |

| 15927 | 1/2-13 | 3/4 | $115.00 | |

| 15926 | 7/16-20 | 3/4 | $105.00 | |

| 15925 | 7/16-14 | 3/4 | $105.00 | |

| 15924 | 3/8-24 | 3/4 | $105.00 | |

| 15923 | 3/8-16 | 3/4 | $105.00 | |

| 15922 | 5/16-24 | 1/2 | $105.00 | |

| 15921 | 5/16-18 | 1/2 | $105.00 | |

| 15920 | 1/4-28 | 1/2 | $105.00 | |

| 15919 | 1/4-20 | 1/2 | $105.00 | |

| 15918 | 12-28 (.216) | 13/32 | $130.00 | |

| 15917 | 12-24 (.216) | 13/32 | $130.00 | |

| 15915 | 10-24 (.190) | 13/32 | $125.00 | |

| 15914 | 8-36 (.164) | 13/32 | $125.00 | |

| 15913 | 8-32 (.164) | 13/32 | $125.00 | |

| 15912 | 6-40 (.138) | 5/16 | $125.00 | |

| 15911 | 6-32 (.138) | 5/16 | $125.00 | |

| 15910 | 5-44 (.125) | 5/16 | $125.00 | |

| 15909 | 5-40 (.125) | 5/16 | $125.00 | |

| 15908 | 4-48 (.112) | 5/16 | $125.00 | |

| 15907 | 4-40 (.112) | 5/16 | $125.00 | |

| 15906 | 3-56 (.099) | 1/4 | $138.00 | |

| 15905 | 3-48 (.099) | 1/4 | $138.00 | |

| 15904 | 2-64 (.086) | 1/4 | $141.00 | |

| 15902 | 1-72 (.073) | 1/4 | $141.00 | |

| 15901 | 1-64 (.073) | 1/4 | $141.00 | |

| 15965 | M24 x 3 | 1 | $260.00 | |

| 15964 | M22 x 1.5 | 1 | $232.00 | |

| 15963 | M20 x 1.5 | 7/8 | $219.00 | |

| 15962 | M16 x 2 | 7/8 | $188.00 | |

| 15961 | M14 x 1.5 | 7/8 | $157.00 | |

| 15960 | M14 x 2 | 7/8 | $157.00 | |

| 15957 | M10 x 1.25 | 3/4 | $135.00 | |

| 15956 | M10 x 1.5 | 3/4 | $135.00 | |

| 15954 | M6 x 1 | 1/2 | $125.00 | |

| 15953 | M5 x .8 | 13/32 | $148.00 | |

| 15948 | M1.6 x .35 | 1/4 | $164.00 | |

| 15900 | 0-80 (.060) | 1/4 | $141.00 |

Master Setting Plugs Class "W"

Master setting plugs, specifically Class W, are precision-calibrated cylindrical plugs with highly accurate dimensions. These setting plugs serve as reference standards for calibrating and setting various measuring instruments, including Tri-Roll Comparators like the Segment Thread Comparator (SPC). Class W denotes a very tight tolerance, indicating an exceptional level of precision in the manufacturing of these plugs.

Typically crafted from materials with excellent dimensional stability and wear resistance, such as tool steel or tungsten carbide, Class W master setting plugs undergo meticulous manufacturing processes to ensure their internal dimensions conform to stringent accuracy standards. Master setting plugs are employed to calibrate the Tri-Roll Comparator. This process ensures that the SPC accurately measures the dimensions of external threads. The master setting plug establishes a reference size for the pitch diameter of the external thread.

The SPC is then adjusted or set based on this known dimension. After calibration, the master setting plug serves as a verification standard. It allows operators to check the accuracy and reliability of the SPC's measurements periodically. Operators adjust the Segment Thread Comparator to match the dimensions of the master setting plug. This adjustment ensures that the SPC provides accurate and consistent measurements when inspecting external threads. By using a Class W master setting plug, operators can have confidence in the precision and accuracy of their measurements.

This is crucial for maintaining high-quality standards in the production of threaded components.These plugs are integral for achieving precise and consistent measurements in applications where tight tolerances are essential, such as in industries like aerospace, automotive, and manufacturing. Master setting plugs, Class W, play a vital role when used in conjunction with a Tri-Roll Comparator, specifically the Segment Thread Comparator (SPC).

In summary, Class W master setting plugs are essential tools for achieving precision in the calibration and setting of Tri-Roll Comparators like the Segment Thread Comparator. Their use provides a reliable reference standard for thread measurements, contributing to quality assurance and efficiency in threaded component manufacturing.