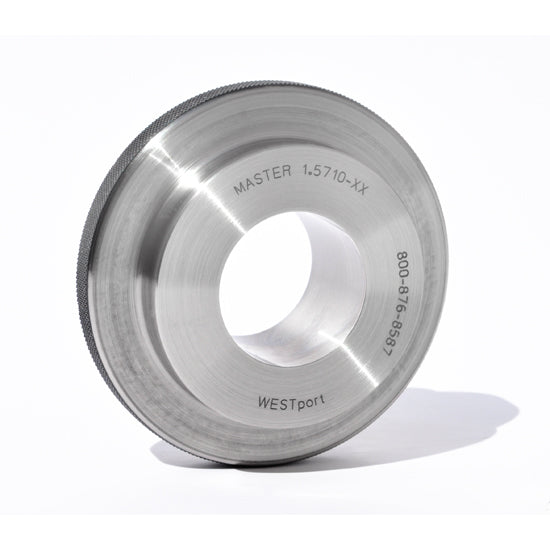

Cylindrical Ring Gage - Steel - Inch - Steel - X - .3651-.510 - GO / NOGO

Cylindrical ring gages also referred to as plain ring gages efficiently inspect the external dimensions of manufactured parts. Ring gages can also can be used to set an instrument, air or electronic. Cylindrical ring gages come in different designs based on size. Ring gages below 1.510 are manufactured without a flange outer diameter Ring gages above 1.510" are manufactured with a flanged diameter. Removing the excess material from the outside diameter of the ring gage lightens up the weight of the gage providing for easier use by the operator.

Plain ring gages are ideal for use as master and GO NOGO gaging. An annular groove in the periphery of the NO GO ring distinguishes it from the GO ring. With GO NOGO ring gaging, an inspector can quickly pass or fail parts without taking time consuming readings from a measuring instrument. Plain ring gages can be used to set air gages, bore gages and internal micrometers. By using the same size master ring gages, lead errors on measurements can be eliminated. Ring gage blanks are put through a stabilization process, cycling them through temperature extremes from -130°F to +300°F. The ring gage is then inspected for size and class in a temperature controlled lapping room and the final inspection is completed in our environmentally controlled metrology laboratory. To ensure maximum wearability all ring gages are lapped to size and polished.

Ring gages are manufactured in accordance with ANSI/ASME B89.1.6 - 1984. Gage blanks meet all the requirements of B47.1-1981. Roundness and taper of ring gages will not exceed 50% of the applicable gagemakers size tolerance and are non cumulative. Gages are ring lapped to size and hand polished providing for superior accuracy and ensuring maximum gage wearability. Plain ring gage sizes are available from .015" to 29". Ring gages above 5.510" are supplied with tapped holes for ball handles unless specified. WESTport Gage provides a Certificate of Accuracy, traceable to NIST (National Institute of Standards and Technology), free of charge with every cylindrical ring gage.

- Ring Gages inspect the external dimensions of manufactured parts

- Ring Gages can also be used to set an instrument, air or electronic

- An annular groove in the periphery of the NO GO ring distinguishes it from the GO ring

- Gagemakers tolerance will be applied minus on the GO and plus on the NO GO

- Gages are ring lapped to size and hand polished to provide superior accuracy and wearability

- Non-gage areas are black oxided and ring faces are surface ground

- Roundness and taper will not exceed 50% of the applicable gagemakers size tolerance and are non-accumulative

- Ring gages above 5.510" are supplied with tapped holes for ball handles unless specified

- Ring gages are manufactured in accordance with ANSI/ASME B89.1.6 Gage blanks meet all the requirements of B47.1

- Ring gage blanks go through a stabilization process, cycling through temperature extremes from -130°F to +300°F

- Ring gages are inspected for size and class in a temperature-controlled lapping room

- Final inspection of ring gages is completed in a separate, environmentally controlled ISO 17025 laboratory

- Available in steel, chrome and carbide

- Free NIST certificate of accuracy

| part | CRGSI-7X |

| class | X |

| member | GO-/-NOGO |

| Size Range | .3651-.510 |

| Measure | Inch |

| material | Steel |