View WESTports selection of Cylindrical Taper Gages

--------------------------------------------------------------------------------

Cylindrical Taper Gage Descriptions

WESTport Gage manufactures cylindrical taper gages to meet your gaging needs. We use specially modified equipment for grinding and measuring a taper.

The ANSI standard on Machine Tapers can be a bit confusing to the average user. These standards were written for the machine tool builder and tool holder manufacturer, not the gage manufacturer or the customer trying to measure machine tapers. If you order a taper ring and plug gage to the ANSI standard they will not blue to each other. The machine taper ID is made with a decreasing taper, while the tool holder’s OD is made with an increasing taper. The proper ordering procedure is to order a PLUG to the standard and a “check ring” to check the plug for wear, and vise versa the RING to the plug. All Standard Tapers manufactured to ASME/ANSI B5.10 class Z unless otherwise specifie.

Jarno Taper Gage

Jarno tapers range from a Number 2 to a Number 20. The diameter of the big end in inches is always the taper size divided by 8, the small end is always the taper size divided by 10 and the length is the taper size divided by 2. For example a Jarno #7 measures 0.875" (7/8) across the big end. The small end measures 0.700" (7/10) and the length is 3.5" (7/2).

Morse Taper Gage

Description & Features

- The Morse Taper Gages, both Plug and Ring type are made of superior quality high Carbon Chrome alloy Steel.

- Heat treated and, hardened to 58-60 HRC, to provide a high degree of wear resistance.

- Fine lapped to get maximum seating and surface finish.

- Rough ground and kept for a long period of time before finishing is given; this is done to prevent any distortions and ensure stability through their use.

Common Uses

- The MORSE TAPER Plain Gages are used to check female tapers of components, IE. Machine Spindle Tapers, Socket Tapers.

- The MORSE TAPER Plain Ring Gages are used to check external tapers of components , IE., Machine Spindle Tapers, Socket Tapers.

- The MORSE TAPER Tanged Plug Gages are used to check female tanged type tapers, IE. Drilling Machine Spindles, drill Sockets.

- The MORSE TAPER Tanged Ring Gages are used to check male tanged type tapers, IE. Drill Sockets, extension Drill Sockets.

Sizes

Morse Tapers come in eight sizes identified by number between 0 and 7. Often this is abbreviated as MT followed by a digit, for example a Morse taper number 4 would be MT4. The MT2 taper is the size most often found in drill presses up to 1/2" capacity.

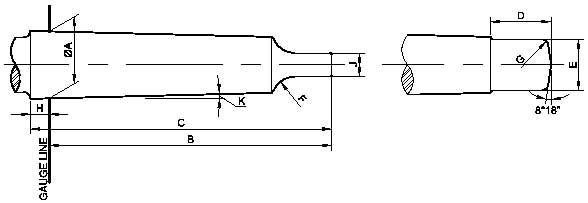

End types

Morse tapers can have two types of ends: tang (illustrated) to facilitate removal with a drift threaded to be held in place with a draw bar The taper itself is roughly 5/8" per foot, but exact ratios and dimensions for the various sizes of tang type tapers are given below.

|

Morse Taper Dimensions (mm) |

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

Morse Taper |

Taper |

A |

B (max) |

C (max) |

D (max) |

E(max) |

F |

G |

H |

J |

K |

|

0 |

19.212:1 |

9.045 |

56.5 |

59.5 |

10.5 |

6 |

4 |

1 |

3 |

3.9 |

1°29'27" |

|

1 |

20.047:1 |

12.065 |

62 |

65.5 |

13.5 |

8.7 |

5 |

1.2 |

3.5 |

5.2 |

1°25'43" |

|

2 |

20.020:1 |

17.780 |

75 |

80 |

16 |

13.5 |

6 |

1.6 |

5 |

6.3 |

1°25'50" |

|

3 |

19.922:1 |

23.825 |

94 |

99 |

20 |

18.5 |

7 |

2 |

5 |

7.9 |

1°26'16" |

|

4 |

19.254:1 |

31.267 |

117.5 |

124 |

24 |

24.5 |

8 |

2.5 |

6.5 |

11.9 |

1°29'15" |

|

5 |

19.002:1 |

44.399 |

149.5 |

156 |

29 |

35.7 |

10 |

3 |

6.5 |

15.9 |

1°30'26" |

|

6 |

19.180:1 |

63.348 |

210 |

218 |

40 |

51 |

13 |

4 |

8 |

19 |

1°29'36" |

|

7 |

19.231:1 |

83.058 |

285.75 |

294.1 |

34.9 |

- |

- |

19.05 |

- |

19 |

1°29'22" |

Brown & Sharpe Taper Gage

Brown & Sharpe tapers, standardized by the eponymous company are an alternative to the more-commonly seen Morse taper. Like the Morse, these have a series of sizes, from 1 to 18, with 7, 9 and 11 being the most common. Actual taper on these is within a close range of .500" per foot.

Brown & Sharpe tapers, standardized by the eponymous company are an alternative to the more-commonly seen Morse taper. Like the Morse, these have a series of sizes, from 1 to 18, with 7, 9 and 11 being the most common. Actual taper on these is within a close range of .500" per foot.

Taper Dimensions Specification Table: Morse - Brown & Sharpe - Jarno - Jacobs

|

Taper Name |

Large End |

Taper/ft |

Taper/in |

Angle in dIErees |

Small End |

Length |

|

#0 Morse |

0.356 |

0.625 |

0.052 |

1.491 |

0.252 |

2.000 |

|

#1 Morse |

0.475 |

0.599 |

0.050 |

1.429 |

0.369 |

2.130 |

|

#2 Morse |

0.700 |

0.599 |

0.050 |

1.431 |

0.572 |

2.560 |

|

#3 Morse |

0.938 |

0.602 |

0.050 |

1.438 |

0.778 |

3.190 |

|

#4 Morse |

1.231 |

0.623 |

0.052 |

1.488 |

1.020 |

4.060 |

|

#4-1/2 Morse |

1.500 |

0.624 |

0.052 |

1.489 |

1.266 |

4.500 |

|

#5 Morse |

1.748 |

0.632 |

0.053 |

1.507 |

1.475 |

5.190 |

|

#6 Morse |

2.494 |

0.626 |

0.052 |

1.493 |

2.116 |

7.250 |

|

#7 Morse |

3.270 |

0.624 |

0.052 |

1.489 |

2.750 |

10.000 |

|

#1 Brown & Sharpe |

0.239 |

0.502 |

0.042 |

1.198 |

0.200 |

0.940 |

|

#2 Brown & Sharpe |

0.300 |

0.502 |

0.042 |

1.198 |

0.250 |

1.190 |

|

#3 Brown & Sharpe |

0.375 |

0.502 |

0.042 |

1.198 |

0.313 |

1.500 |

|

#4 Brown & Sharpe |

0.421 |

0.502 |

0.042 |

1.199 |

0.350 |

1.690 |

|

#5 Brown & Sharpe |

0.539 |

0.502 |

0.042 |

1.197 |

0.450 |

2.130 |

|

#6 Brown & Sharpe |

0.600 |

0.503 |

0.042 |

1.201 |

0.500 |

2.380 |

|

#7 Brown & Sharpe |

0.720 |

0.502 |

0.042 |

1.197 |

0.600 |

2.880 |

|

#8 Brown & Sharpe |

0.899 |

0.501 |

0.042 |

1.196 |

0.750 |

3.560 |

|

#9 Brown & Sharpe |

1.078 |

0.501 |

0.042 |

1.196 |

0.900 |

4.250 |

|

#10 Brown & Sharpe |

1.260 |

0.516 |

0.043 |

1.232 |

1.045 |

5.000 |

|

#11 Brown & Sharpe |

1.498 |

0.501 |

0.042 |

1.196 |

1.250 |

5.940 |

|

#12 Brown & Sharpe |

1.797 |

0.500 |

0.042 |

1.193 |

1.500 |

7.130 |

|

#13 Brown & Sharpe |

2.073 |

0.500 |

0.042 |

1.194 |

1.750 |

7.750 |

|

#14 Brown & Sharpe |

2.344 |

0.500 |

0.042 |

1.194 |

2.000 |

8.250 |

|

#15 Brown & Sharpe |

2.615 |

0.500 |

0.042 |

1.194 |

2.250 |

8.750 |

|

#16 Brown & Sharpe |

2.885 |

0.500 |

0.042 |

1.194 |

2.500 |

9.250 |

|

#17 Brown & Sharpe |

3.156 |

0.500 |

0.042 |

1.194 |

2.750 |

9.750 |

|

#18 Brown & Sharpe |

3.427 |

0.500 |

0.042 |

1.194 |

3.000 |

10.250 |

|

#2 Jarno |

0.250 |

0.600 |

0.050 |

1.432 |

0.200 |

1.000 |

|

#3 Jarno |

0.375 |

0.600 |

0.050 |

1.432 |

0.300 |

1.500 |

|

#4 Jarno |

0.500 |

0.600 |

0.050 |

1.432 |

0.400 |

2.000 |

|

#5 Jarno |

0.625 |

0.600 |

0.050 |

1.432 |

0.500 |

2.500 |

|

#6 Jarno |

0.750 |

0.600 |

0.050 |

1.432 |

0.600 |

3.000 |

|

#7 Jarno |

0.875 |

0.600 |

0.050 |

1.432 |

0.700 |

3.500 |

|

#8 Jarno |

1.000 |

0.600 |

0.050 |

1.432 |

0.800 |

4.000 |

|

#9 Jarno |

1.125 |

0.600 |

0.050 |

1.432 |

0.900 |

4.500 |

|

#10 Jarno |

1.250 |

0.600 |

0.050 |

1.432 |

1.000 |

5.000 |

|

#11 Jarno |

1.375 |

0.600 |

0.050 |

1.432 |

1.100 |

5.500 |

|

#12 Jarno |

1.500 |

0.600 |

0.050 |

1.432 |

1.200 |

6.000 |

|

#13 Jarno |

1.625 |

0.600 |

0.050 |

1.432 |

1.300 |

6.500 |

|

#14 Jarno |

1.750 |

0.600 |

0.050 |

1.432 |

1.400 |

7.000 |

|

#15 Jarno |

1.875 |

0.600 |

0.050 |

1.432 |

1.500 |

7.500 |

|

#16 Jarno |

2.000 |

0.600 |

0.050 |

1.432 |

1.600 |

8.000 |

|

#17 Jarno |

2.125 |

0.600 |

0.050 |

1.432 |

1.700 |

8.500 |

|

#18 Jarno |

2.250 |

0.600 |

0.050 |

1.432 |

1.800 |

9.000 |

|

#19 Jarno |

2.375 |

0.600 |

0.050 |

1.432 |

1.900 |

9.500 |

|

#20 Jarno |

2.500 |

0.600 |

0.050 |

1.432 |

2.000 |

10.000 |

|

#0 Jacobs |

0.250 |

0.592 |

0.049 |

1.412 |

0.228 |

0.440 |

|

#1 Jacobs |

0.384 |

0.925 |

0.077 |

2.207 |

0.333 |

0.660 |

|

#2 Jacobs |

0.559 |

0.979 |

0.082 |

2.335 |

0.488 |

0.880 |

|

#2 Short Jacobs |

0.549 |

0.979 |

0.082 |

2.335 |

0.488 |

0.750 |

|

#3 Jacobs |

0.811 |

0.639 |

0.053 |

1.525 |

0.746 |

1.220 |

|

#4 Jacobs |

1.124 |

0.629 |

0.052 |

1.501 |

1.037 |

1.660 |

|

#5 Jacobs |

1.413 |

0.620 |

0.052 |

1.480 |

1.316 |

1.880 |

|

#6 Jacobs |

0.676 |

0.623 |

0.052 |

1.487 |

0.624 |

1.000 |

|

#33 Jacobs |

0.624 |

0.762 |

0.064 |

1.818 |

0.561 |

1.000 |